Houston’s Premier Mold Design Services

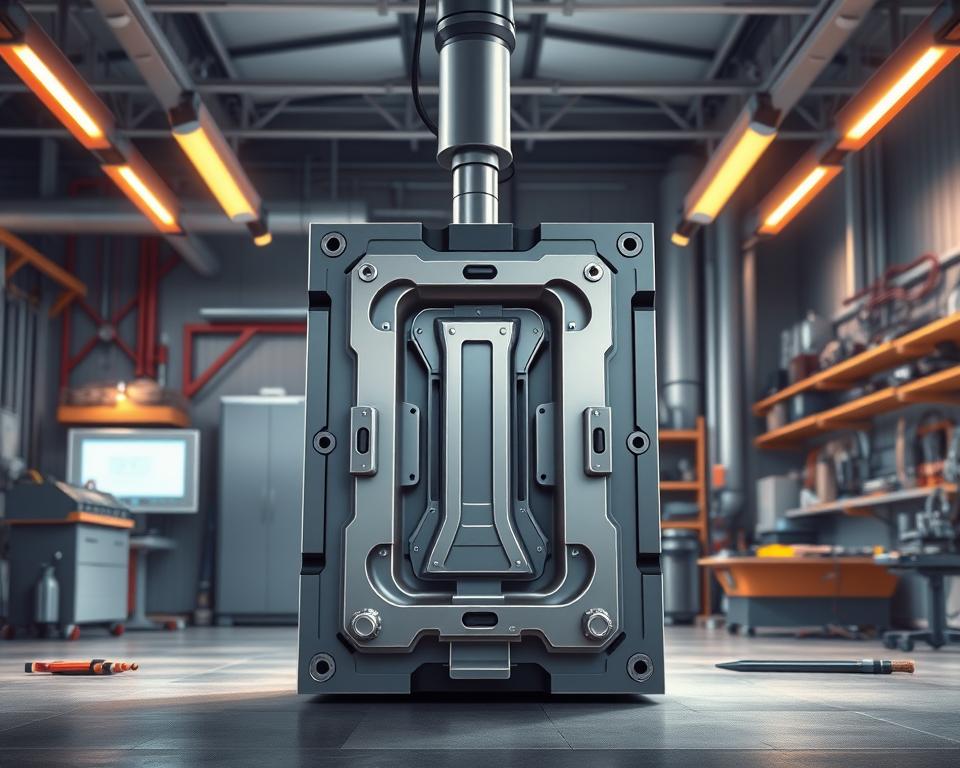

By 2025, the global injection molded plastics market will reach $440 billion. Such expansion highlights why expert mold design is essential. They create high-quality custom mold designs for diverse industries. Among Houston companies, Lowrance Machine is renowned for mold design. They offer innovative solutions for automotive, aerospace, and consumer products.

Lowrance Machine uses advanced technologies like CAD software and 3D printing. Their specialists deliver efficient, highly precise mold production. With their extensive experience and technical skills, they are a reliable partner for businesses. Learn how their industrial molds Houston capabilities improve your initiatives and align with modern market requirements.

Understanding the Importance of Mold Design Services

In manufacturing, mold design services directly influence quality and process efficiency. The role of mold design is immense; it shapes the performance and longevity of products. By prioritizing professional mold design, firms reduce costs and improve quality measures.

Seasoned professionals at Lowrance Machine illustrate the benefits of expertise. They dive deep into client needs and work hand-in-hand to craft custom solutions. By employing cutting-edge methods like 3D modeling and CAD, they help businesses create molds that adhere to high standards.

Choosing top-notch mold design services boosts product performance and drives business success. With optimized mold design, manufacturing runs smoothly and firms gain market advantage.

Houston Mold Design: Service Categories

Lowrance Machine offers a wide range of mold design Houston services, tailored to meet specific industry needs. Knowing the different types of mold services helps businesses choose the best for their projects. Key categories include:

- Bespoke Mold Designs: Tailored mold designs crafted to precise specs.

- Prototyping: Prototype mold development for pre-production testing.

- Injection Molds Houston: Precision-engineered injection molds built to last.

- 3D Modeling: 3D-model-driven design for superior precision.

- Repair and Maintenance: Services aimed at extending the lifespan of existing molds through essential repairs and maintenance.

Each service is designed to streamline production, improve product quality, and ensure cost-efficiency. Knowing the service spectrum lets companies tailor mold design to their operational objectives.

Why Hire Professional Mold Designers

Choosing professional mold design experts brings numerous advantages to manufacturing processes. Expect greater precision, longer tool life, and faster cycles. Bespoke design drives superior product standards and uniformity.

Experienced mold design experts offer insights that streamline production. Their knowledge ensures designs meet industry standards and unique specifications. This collaboration fosters innovation and improves product lifecycles.

Cost-effectiveness is a significant benefit. Modern techniques curb scrap and shorten lead times. These improvements lead to better budgets and healthier profit margins. Fast-turnaround designs accelerate product launches.

Overall, professional mold services underpin manufacturing success. They focus on boosting throughput and product excellence.

Cutting-Edge Mold Design Methods

Technological progress has revolutionized mold design. Lowrance Machine leads the way with its cutting-edge mold design techniques. These methods enhance throughput and refine product excellence. High-end tools simplify bespoke mold crafting while reducing expenses.

3D printing is a standout among these techniques, enabling quick prototyping and complex designs. It significantly reduces material waste compared to traditional methods. Simulation platforms enable virtual mold testing and enhancement for superior performance and throughput.

In Houston, mold design experts are embracing these modern strategies. Companies are gaining a competitive advantage by leveraging digital design tools and advanced fabrication methods. They support dynamic, client-focused design cycles that address varied sector requirements.

| Technique | Description | Benefits |

|---|---|---|

| 3D Printing | Employs layer-by-layer building for quick mold production. | Shortens delivery times and cuts scrap. |

| Virtual Testing Tools | Enables digital prototype testing and refinement. | Enhances accuracy and optimizes performance. |

| CAD Platforms | Integrates advanced software for precise mold specifications. | Enables tailored designs and quick edits. |

To Summarize

Professional mold design underpins both efficient operations and quality products in Houston. Professional mold design services offer expertise to tackle mold development challenges. They tailor solutions to individual requirements for optimal results.

Lowrance Machine is a top name in mold design, known for its dedication to precision and collaboration with clients. Custom designs and modern tools offered by these experts keep producers competitive. Engaging experts boosts standards and refines processes.

Choosing expert mold design services in Houston prioritizes both excellence and speed. Companies will satisfy market demands and sharpen their competitive edge. Embracing these expert offerings is key to thriving in a challenging marketplace.