Shurflo Fluid Pump Schematic – Parts Supply for Installations

Incorrect installation of water pumps can significantly lower their performance by up to 30%. It’s vital to comprehend the mechanics of the Shurflo Water Pump diagram for optimal operation and durability. Each element within the schematic fulfills a key function in the pump’s function. This article examines the importance of comprehending these Shurflo fittings, employing the schematic to demonstrate their assembly and how they work together.

Parts Supply for Installations is your preferred provider for every Shurflo Water Pump component essential for assembly and servicing. Learning via the Shurflo Pump parts diagram empowers users to proficiently manage installation and servicing. This foundation aids in making wise selections for the optimal and reliable performance of their Water Pump units.

Grasping Shurflo Water Pumps

Shurflo Pump systems are at the crossroads of modernity and utility, satisfying the needs of various uses. This portion seeks to provide an in-depth overview of Shurflo Water Pump models, their particular applications, and the benefits of choosing these pumps. They are famed for their state-of-the-art design and efficiency.

Summary of Shurflo Pump Types

Shurflo’s assortment features pumps like the membrane and agricultural series, engineered to meet varied demands. The diaphragm models are praised for their solid construction and ability to transfer fluids. Notable examples include the 2088-343-135 and 2088-343-500 deliver robust performance with notable flow and pressure capabilities.

The farm series, conversely, is designed for optimal fluid conveyance in greenhouse applications.

Uses of Shurflo Pumps

The flexibility of Shurflo Pumps enables their use in a diversity of environments. They are commonly used for:

- Farming: Provides solutions for crop irrigation and fertilization.

- Recreational Vehicles: Maintains a steady water flow with safe pressure levels.

- Residential: Well-suited for landscaping and home fluid systems.

This adaptability permits these pumps to incorporate easily into diverse configurations, proving their versatility.

Benefits of Employing Shurflo Pump Systems

Opting for Shurflo Pump systems brings several perks. Their ability to self-prime erases the inconvenience of manual operation startup. They also have resilience to chemicals, ensuring longevity in harsh environments. Convenient access to Shurflo membrane Pump parts streamlines servicing, boosting service life while minimizing interruptions. Additional benefits of Shurflo Pumps include:

- Stable performance that can be customized with adjustable pressures.

- Easy installation supported by the Shurflo Pump parts catalog.

- Various connection options for smooth system integration.

With these attributes, Shurflo Pumps promise consistent performance and dependability. They guarantee ongoing functionality, instilling trust in their performance.

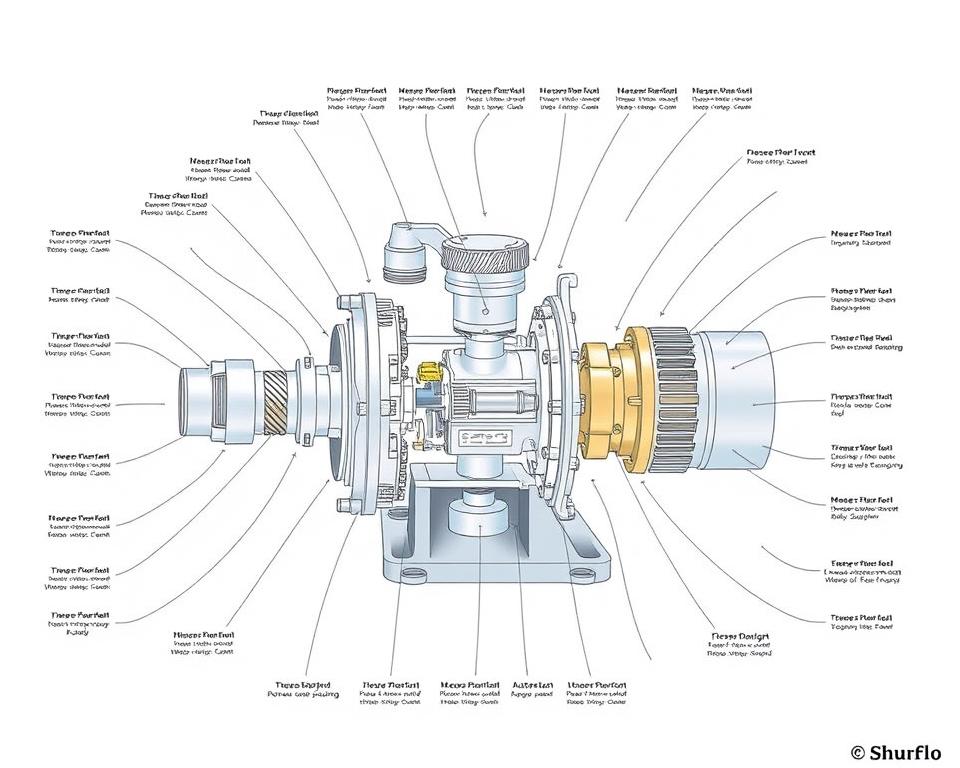

Understanding the Shurflo Water Pump Diagram and Its Value

The Shurflo Pump schematic is vital for grasping its components and functions. By reviewing the Shurflo Water Pump schematic, users can construct, diagnose, and uphold effectiveness. This schematic is crucial for determining the needed Shurflo Water Pump parts. Accurate assembly ensured through the diagram secures peak performance.

Key Components in the Diagram

The Shurflo Pump schematic showcases critical components vital for the pump’s functionality:

- Motor: The motor, the central unit of the Pump, powers the rotor, delivering flow rates between 41 and 168 GPM.

- Membrane: Assists in maintaining consistent flow and pressure.

- Check Valves: Crucial for preventing backflow, these devices ensure that liquid is directed properly.

- Casing: With a maximum pressure of 200 PSI, the casing secures longevity.

How to Read the Shurflo Water Pump Schematic

To read the Shurflo Water Pump diagram, one must observe specific symbols and notations:

- Learn the arrangement of components depicted in the diagram.

- Determine the movement direction marked by arrows.

- Review annotations for specifics such as cable gauges and installation choices.

Mastering this diagram is vital for proper assembly, maintenance, and identifying key components.

Installation of Shurflo Water Pumps

Installing a Shurflo Water Pump can make any water system more functional. Understanding the required procedures and parts is vital for a good installation. This instructional overview outlines key actions and required instruments for a triumphant installation.

Step-by-Step Guide to Installing a Shurflo Pump

- Start with collecting every instrument for shurflo pump setup. Make sure you have items like a suitable screwdriver, wrench, and 50-mesh strainer.

- Install the 50-mesh strainer at the Pump’s intake. It is advisable to employ a flexible hose for inlet connections to minimize strain on fittings.

- Use a 1/2” to 3/8” barb splicer for securing tubing connections. To avoid leaks, opt for strengthened tubing paired with Oetiker clamps.

- The pump should be wired to a properly grounded outlet. A certified electrician is recommended for this task to comply with local regulations.

- Charge the accumulator tank with 50 PSI of clean air or nitrogen. This is important for the best pressure performance.

- Install a SHURflo 65 psi valve to lower water pressure at the inlet to secure the proper pressure setting.

- Finalize the configuration by joining every element. Don’t exceed the motor’s amperage rating; thermal breakers offer extra safety.

- Conduct a system test and verify the pressure switch operates correctly.

Necessary Equipment and Components for Setup

| Element | Details |

|---|---|

| 50-mesh screening | Removes contaminants at the inlet for superior operation. |

| Flexible hose | Preferred for inlet use, minimizing pressure on connectors. |

| Barb connector | Facilitates a firm connection between tubes with a 1/2” to 3/8” adapter. |

| Pressure tank | Pre-charged to 50 PSI for maintaining pressure. |

| Pressure regulator | Regulates operation by monitoring pressure conditions. |

| Wiring components | Essential for proper electrical hookup, following local codes. |

| SHURflo 65 psi pressure reducer valve | Ensures steady pressure by reducing the water pressure at the inlet. |

Diagnosing Frequent Problems in Shurflo Pumps

Learning to fix common issues with shurflo pumps improves their functionality. This part delivers a problem-solving manual. It assists in identifying and remedying common issues to secure continuous performance. Problems related to operation, flow, and acoustics are addressed with effective fixes.

Frequent Faults and Corrections

Various conditions may result in malfunctions with Shurflo Pumps. Below are key problems and their solutions:

- Pump operates without liquid movement: Check the freshwater tank level, inspect the water line for blockages or damage, ensure proper priming, and verify the water pump’s functionality.

- Pump won’t turn on after winterization: Examine winterization methods, ascertain all valves are operable, inspect electrical setups, and search for signs of damage.

- Pump intermittently starting and stopping: Look for any leaks, remove trapped air, adjust pressure controls accordingly, and test both the Pump and its pressure switch.

- Noisy pump: Examine connections for looseness, install supportive padding, shield pipes, and confirm accurate installation.

Troubleshooting Manual for Shurflo Pumps

A complete Shurflo Pump troubleshooting guide helps rapidly pinpoint problems. The following table summarizes typical issues and corrective actions:

| Common Issue | Possible Reasons | Solutions |

|---|---|---|

| Operation without liquid movement | Low freshwater tank, blockages, improper priming | Examine reservoir, review piping, confirm Pump operation |

| Pump won’t turn on | Incorrect winter procedures, blocked valves, wiring faults | Reexamine procedures, unlock valves, inspect electrical links |

| Pump cycles on and off | Faulty seals, air pockets, pressure misconfigurations | Check system integrity, purge air, calibrate pressure |

| Noisy pump | Loose connections, inadequate installation | Secure fittings, implement vibration damping, shield piping |

Comprehending the shurflo pump exploded view aids in identifying the parts causing problems is essential for accurate diagnosis. Observing these steps guarantees proper maintenance and dependable functioning.

The Bottom Line

Understanding the Shurflo Water Pump schematic is vital for achieving maximum Pump efficiency.

Employed across sectors such as RVs and agricultural applications, proper installation is fundamental for reliable results.

Familiarity with the diagram’s elements allows for efficient installation and sustained maintenance.

For acquiring every necessary Shurflo Pump part and service, Installation Parts Supply is unrivaled, delivering extensive service along with vital instruments and elements. Such support guarantees proper assembly. Through correct installation practices and proper maintenance of elements such as the strainer, Pump durability and performance are improved.

This write-up provides the insights needed to enhance overall Shurflo system operation. By taking advantage of Shurflo pumps and implementing installation tips, users are prepared to face any challenges with assurance.